What is Iron on Edging?

2 Comments7 May 2014 | edgeband.co.uk

| Iron on edging, also referred to as edge banding, is a tape that is applied to the exposed edge of materials such as chipboard or MDF to give a professional finished appearance. It is relatively inexpensive and very easy to apply. The edging is coated on the back with an adhesive and is simply heated with a normal household iron on a medium setting, the glue melts and forms a strong bond between the edge and the tape. It is then trimmed with a trimming tool or Stanley blade and lightly sanded. See our guide on applying your iron on edging. |  |

| The edging is coated on the back with an adhesive and is simply heated with a normal household iron on a medium setting, the glue melts and forms a strong bond between the edge and the tape. It is then trimmed with a trimming tool or Stanley blade and lightly sanded. See our guide on applying your iron on edging. You can apply the edging tape to shelves, worktops & cabinets. It is used in kitchens, bathrooms, bedrooms and living areas, by professionals, DIY enthusiasts and crafters. |

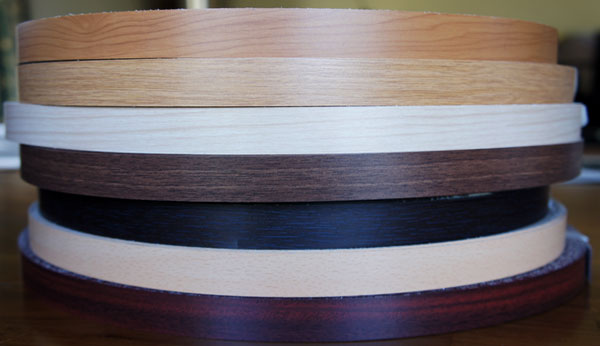

| Several types are available depending on your project. Iron on veneer is a thin slice of real wood that can give the appearance of a solid wood finish, there are many wood edging species available, examples include iron on Oak veneer, Maple, Walnut, Birch and Cherry. |  |

| Iron on Melamine edging is a cheaper option and is used extensively in the manufacture of kitchen and bedroom furniture. It is a specialist resin-saturated paper which is lacquered to give it resilience. It comes in a wide range of colours and wood effects and several finishes including matt and gloss. |

| In summary iron on edging is a quick and easy way to hide the exposed edge of a variety of materials. It comes in lots of different colours and finishes and in several widths and lengths to suit every project. |

I have purchased a sample of oak (white ) edging and as a result purchased 5mm of supposedly the same veneer.

It does not resemble in any way other than the colour the saample. So pointless sending for samples prior to buying . In case it was bad luck, I purchase another roll which again does not resemble the sample. I don't quite know why the 5 m roll should be so different, but given that 2 rolls bought at different times are the same and the sample has totally different grain why don't you send samples which are more accurately depicting the 5 m roll grain.

Hi, we have also sent you an email directly as well as responding here. The veneers are a natural product made of real wood, this means that the colour and grain will vary as they are very likely from different rolls, batches and different trees. For this reason samples cannot really be used for colour or grain matching, they are really just a guide to ensure that you have selected the correct veneer species for your project. If you are looking for a more uniform product then we would suggest something man-made which are printed, this means that the grain and colour will always be the exactly same, for example a wood effect melamine edging. Best regards.